If you’re operating in a competitive market, you’ll need tons of techniques to stay above the competition and remain relevant in the market.

One such technique you’ll find invaluable is the cost leadership strategy used in strategic management.

From top brands like:

Amazon to Walmart and McDonalds to less known but highly successful brands like Primark, cutting operational costs to offer products or services at the cheapest rates has been a major game-changer that is giving large businesses more market dominance and significant market share.

The cost strategy is decades old, but it’s still relevant today when it comes to enhancing business processes and creating a winning marketing strategy.

By learning how this strategy works, and how successful companies are implementing it, you can develop a unique cost-saving strategy that will give you an edge in the market you operate in.

What is Cost Leadership Strategy?

It’s a strategy used by brands to gain a reputation as the provider of the cheapest goods or services in a given market.

The cost leadership strategy is one of the Generic Strategies introduced by renowned author Michael Porter and it can be applied to all products and services, industries and organizations of all sizes.

Brands that are cost leaders in their industry offer top-quality products and services at the lowest possible prices. This strategy helps them to remain competitive, profitable and to stimulate growth.

Practices like reducing profit margin or cutting revenue are not cost-based strategies.

The strategy is about reducing the cost of production so that you can end up with a unit cost of a product or service that is much less than the unit costs of your competitors’ similar products or services.

In other words, your products cost less to produce than your competitors’.

That’s the only way to be a cost leader in your category or industry.

For a brand, the reduction in cost should apply to all the products or services associated with that brand.

You can’t be a reputed brand for low-cost quality items when it’s only one or a few of your products that are offered at a cheaper rate. The affordability should be seen across all spectrum of products and services that your brand offers.

Cost Leadership vs Price Leadership

Cost leadership and price leadership are often used interchangeably though there is a difference.

Price leadership means your products have the reputation of being the cheapest in their category (i.e. the price to purchase is the lowest).

Cost leadership refers to the cost of production being the lowest.

Of course, brands leading on a cost basis have the ability to be the price leader by reducing their prices below that of their competitors.

A brand can be the price leader and not the cost leader with an aggressive pricing strategy but if you are the cost leader then you always have the ability to undercut your competitors.

Some companies, in a bid to win the price war lower prices at the detriment of revenue. This is not sustainable and might lead to incurring significant losses. In contrast, if you can develop a business-level strategy that will help you lower operating costs, you can achieve lower prices and still remain profitable.

PRO Brand Strategy BluePrint

Build Brands Like A Pro Brand Strategist

Advantages and Disadvantages of Cost Leadership Strategy

Striving to become a cost leader has its own pros and cons but one thing is if it’s not effective, the big brands won’t be doing it. Let’s consider some ways the strategy can benefit your business and how things can get tricky as well.

Explore Brand Strategy

Programs & Tools

Pros

Winning Customers’ Loyalty

Cost leaders easily win and attract a large customer base by giving them higher value for lower fees.

No one wants to spend an extra dollar when they can get the same quality for a lesser fee so most people stick with a brand that offers them more for less.

Increase In Revenue

As the customer base grows, the company’s revenue increases and that means

Companies won’t have to run at a loss to remain competitive. Unlike price leadership where businesses tend to reduce their profit margins, the cuts are on the business processes, not revenue.

Market Dominance

The implementation of the strategy will often mean increasing production output by a large purchase of raw materials.

When things are scaled up this way, competitors will find it more difficult to outperform whatever you are doing, and in many cases, you’ll remain the undisputed leader in the category just like Amazon and Walmart.

Cons

Maintaining High-Quality Standards

Things can happen whether it is the prices of raw materials going up or workers requesting a pay raise. When unit costs rise and you still want to maintain your reputation about prices, you might be tempted to compromise on quality and when customers begin to notice this, your brand loyalty wanes.

If you can’t be a cost leader, you can offer superior products with premium pricing instead rather than low pricing on compromised quality.

Mass Production And Sales

Since this strategy pretty much thrives on scaling, you’ll need to mass-produce and get access to a large segment of the market to remain profitable.

Challenges With Flexibility

If as a brand you have developed proprietary technologies to lower the cost of production, you may find it difficult to adapt to new trends when consumer tastes shift and your technology becomes obsolete.

How To Become A Cost Leader

Cost leadership is not easy to attain, it involves making an analysis of your current processes and identifying unique ways to reduce costs. Here are some effective strategies that have been used by businesses to achieve reduced unit costs of their products and services.

Economies of Scale

By implementing the economies of scale, that is increasing the scale of production, you can get large amounts of raw materials for a cheaper price than when they are ordering limited amounts.

Also, by scaling higher, you can stock up raw materials to meet up the demands of a larger market segment.

Access To Working Capital

Keeping competitors from gaining ground on you means having access to the working capital required to meet up with your scale of production and market demand.

You need to be able to secure capital for expansion and keep your operations running as demand grows.

Adopting Innovative Technology

By automating all or part of your production and distribution process, you can increase production output and cut costs.

Technology helps to streamline the process and reduce the number of hands needed to get the work done.

This also means you’ll be spending less on wages.

Eliminate Third Parties In Inventory Procurement

One of the things that increase cost is using contractors and third-party companies to source raw materials for production.

Sourcing directly decreases production costs significantly…

6 Examples of Top Brands That Are Cost Leaders

Whether you are a small business, new entrant or startup, or an established business, you can learn from the following examples of top brands that have successfully implemented this strategy and have recorded a significant cost advantage over their competitors.

#1. IKEA

Based in Sweden, the renowned international furniture retailer operates in 52 countries with 433 stores. To remain competitive, IKEA produces standardized products that can be easily assembled by the end-users.

This enables them to apply the economies of scale and produce in large quantities in ways smaller competitors are unable to match up with.

By producing furniture that can be self-assembled, IKEA eliminates the furniture assembly line, saving costs by reducing employees.

This is why their products are cheap. IKEA also cut costs by manufacturing its products in low-wage countries.

#2. Walmart

Walmart is a multinational retail leader based in the US. The company’s competitive strategy is based on the sales of branded products at cheaper prices.

How do they do it?

Walmart pays considerably low wages to reduce costs. Only people who can accept such wages are welcome to work there.

Besides, there’s a lot of automation in their process. They manage their own distribution chain and own fleet of trucks and trailers in their thousands, cutting costs that would have been spent on third party companies.

Also, the company has a well-coordinated network of stores, distribution centres and suppliers that make it possible for them to order goods in larger quantities and at reduced prices.

#3. McDonald’s

McDonald’s is a household name when it comes to global fast-food chains. McDonald’s hardly hires chefs. Rather what they do is to develop an optimized food preparation process, recruit people and train them to become part of their workforce.

That helps them to save the cost they should have spent hiring experts.

The company also own facilities where they produce ingredients mixes that are used in their meals.

That means they are also saving costs in the raw materials value chain.

#4. Amazon

Amazon, the indisputable king of eCommerce leverages economies of scale, advanced technology, and process automation to maintain a competitive edge.

By increasing processing capabilities and warehouse storage, they are able to get more products out to customers.

By automating the purchase and delivery processes, they also increased operational efficiency.

That’s the reason Amazon can save costs and offer products at cheaper prices.

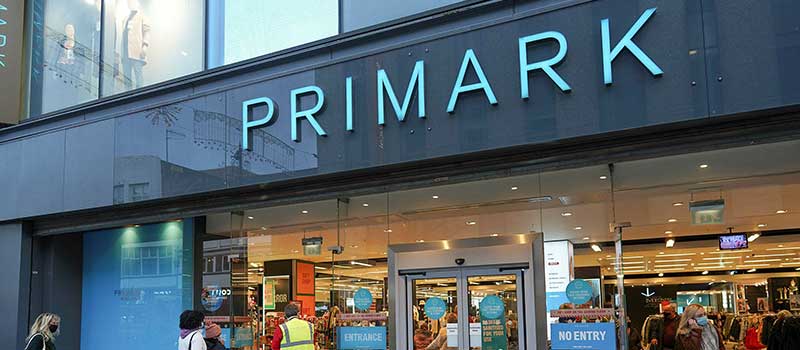

#5. Primark

Primark is a fashion retailer for men, women, kids, and babies. The brand has 370 outlets in 12 countries and boasts the cheapest prices in comparison to other brands in their category.

They achieve this by keeping their operational costs to the lowest.

Primark’s clothes are manufactured in developing countries where labour is cheaper. Also, the company saves costs by adopting a conservative approach to advertising, no elaborate branding campaign, just social media and referrals.

Primark also applies the economies of scale to gain a competitive advantage by stocking in large quantities to cut costs.

They also have a digitized custom clearance and distribution network which significantly reduces the time goods spend to get to warehouses and customers.

#6. RyanAir

RyanAir has been around for almost four decades with 450+ airplanes. It is not only popular as a budget-based airline but it’s also the airline that flies the highest number of routes globally. In past years, it had been reputed as the largest carrier of international passengers.

RyanAir’s strategy of cost leadership is in the provision of air travel at the lowest prices.

One of the ways they achieve this is by flying to small, remote and less congested airports which helps them to keep operating costs low.

By avoiding main airports, they are able to pay low landing and handling fees.

Another thing RyanAir does is that it doesn’t apply a differentiation strategy.

No services that will have their cost passed to the customer are included. No free food, in-flight entertainment, airport lounges, and premium cabins. This helps them to keep a flat rate for everyone.

Another area RyanAir saves cost is in spare parts purchase. Because they keep limited brands and types of aircraft, they are able to procure spare parts in large quantities to save costs.

Getting Started On Your Cost Leadership Journey

Now that you’ve been warmed up on cost leadership strategy, and how it can help you to get ahead of competitors, record significant market share, and win customers’ loyalty, how do you get started? Find some useful suggestions below.

#1. Analyze Existing Operations

Audit your entire production process and analyze the costs of everything that goes into production.

Whether they are the cost of raw materials and/or software, labour cost, administration, or marketing costs. Whatever expense is incurred to create a product or service should be reflected in its sales price.

When you have the numbers, you can identify where it’s possible to reduce costs to achieve certain prices.

#2. Research The Competition

Try to find out what your competitors’ operations processes look like.

Remember, you are not trying to be the price leader but the cost leader, by being the lowest-cost producer.

By understanding your competitors’ operations, you can improve your own process and reduce costs.

#3. Use Technology

Look for ways to reduce human contact in your business so that you’d only need fewer employees and reduce wage bills.

You can introduce intuitive self-service kiosks instead of mounting people on counters.

#4. Make Maximum Use Of Assets

Make the most of your assets for a given period of time.

Do more with what you already have while offering products or services at a cheaper rate.

If you are a service-based company, you can create a strategy where you make maximum use of your service within a time frame. You can charge per hour instead of a flat rate. That way, you can get more people to buy or use your service in a day and offer them cheaper rates.

For production-based companies, increase the scale of production so that you can use your existing facility, machinery and employees to mass-produce.

#5. Reduce Operating Costs

You can cut down on wages or reduce staff strength and introduce new technologies instead. In this age of remote working, some of your workers can work remotely.

That way you won’t have to pay for office rents, electricity or telephone bills, or at least cut down on such costs.

You can also rent warehouses in low-rent areas and outsource some of your operations and production if that helps you to save costs.

Over To You

Cost leadership is not easy to attain in any market. You will often need to apply rigorous cost minimization techniques such as scaling, improved operational efficiencies, getting privileged access to raw materials, or introducing proprietary technology.

It’s not a one-off thing, therefore you should continue to evaluate your process and track your progress. Don’t be tempted to change all your processes at once. You can start by sourcing your raw materials directly and see how that affects costs, then see if introducing new technology will make a difference.

If one thing is not effective, you can revert to the status quo and change another factor.

When you have tested enough and see the difference, you can then begin to implement long-term changes while you also track the results all along.

Once the market reacts, and things begin to level up again, you can go back to the drawing board and see what other changes

On-Demand Digital Program

Brand Master Secrets

Make the transition from hired-gun to highly valued brand strategist in less than 30 days. The systems, frameworks and tools inside this comprehensive program are all you need to level up.